- Sabarkantha, Gujarat

- info@leensanh2o.com

Processing

Our Process

How LEENSAN H2O Delivers Purity

1) RO Plant

The purification process begins at the RO Plant, where raw water is carefully passed through sand and carbon filters. These filters effectively remove dirt, sediments, chlorine, and other harmful substances. As a result, the water becomes cleaner, safer, and suitable for further processing. The purified water is then collected in a storage tank, while the impure water is safely rejected to maintain hygiene standards.

2) UV System

From the storage tank, the water flows into the UV purification system, which provides an additional layer of protection. The powerful UV rays destroy bacteria, viruses, and other microorganisms that may still be present. This ensures the water is not only crystal clear but also 100% safe for human consumption. At this stage, the water has achieved its highest level of purity before moving on to packaging.

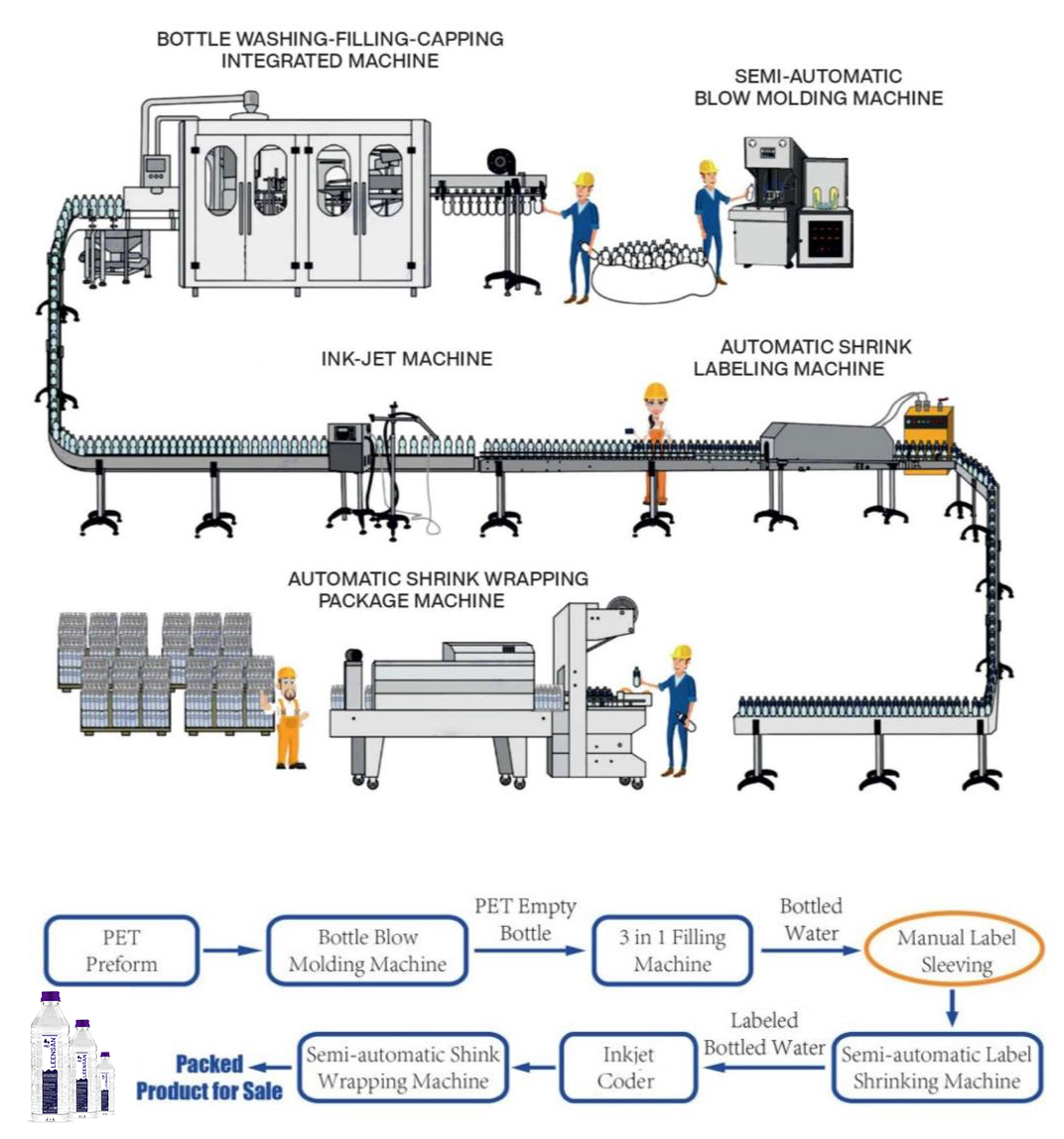

3) Rinsing, Filling & Capping

Once purified, the mineral water is transferred to the Rinsing, Filling & Capping (R.F.C.) machine. Here, every bottle undergoes a thorough rinsing and sterilization process to remove any external contaminants. After sterilization, the bottles are automatically filled with fresh mineral water through nozzles designed for hygiene and precision. Finally, the bottles are tightly sealed with caps to preserve freshness and prevent any leakage or contamination.

4) Batch Coding

To ensure complete transparency, each filled bottle then moves through the batch coding process. In this step, vital details such as the manufacturing date, expiry date, price, and batch number are clearly printed on the bottle. This coding allows both distributors and consumers to have confidence in the product’s quality and safety. It also helps maintain strict accountability and traceability throughout the production and supply chain.

5) PET-BLOWING PROCESS

Our ISI standard approved PET is taken in blowing process. We care to heat at a certain amount of temperature, not too low, not too high, for its perfect shape. Once passing the PET through the oven, we then blow and care to store safely, avoiding the direct floor touching or any hazardous waste. We always make sure to double check before taking it to use.

6) SHRINK-WRAPPING PROCESS

Once the bottle has been labelled and batch coded, we then manage to wrap it in a quantity bundle so that we can stack the whole order. During this process, we take careful consideration of proper amount of micron plastic that is being wrapped to prevent damage while loading and carefully being delivered to you safely.